MASH MAKES x COP28

30 NOV – 12 DEC 2023, DUBAI

We will be there. Do you want to learn more?

Or just have a quick chat? Drop us an email

and let's meet up!

MASH Makes Biofuel

Our Production

Our bio oil is biogenic, meaning that the carbon emitted when it is combusted was originally extracted from the atmosphere via photosynthesis. This makes our oil CO2-neutral, aside from production and transport emissions.

Our Locations

Maintaining a consistent supply of biomass to a biofuel production site is challenging. That’s why our machines were created to be compact and deployable where needed. So instead of one central plant, we can have as many as we need in the locations where they are most relevant.

Our Potential

Our containerised technology is portable and scalable. So, if we want to increase our production somewhere, we can scale up the number of machines for more output. By developing easily replicable technology, we have the potential to capitalise on global biomass availability. This is what will get us to the gigatonne range of carbon removal impact.

Where can you use our fuel?

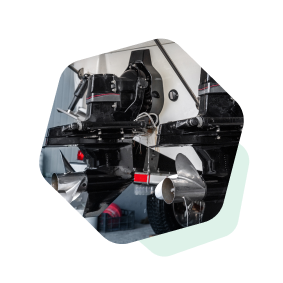

For Marine Use

Available to be used as a dual-purpose additive for methanol, achieving both vastly improved ignition properties and a dramatic reduction in overall blend greenhouse gas (GHG) emission. At 23%, this additive will allow for the operation of methanol in slow and medium-speed 4-stroke engines with few or no modifications needed. The fuel will soon be certified under the ISCC EU and reach standard.

For blending with methanol

MASH fuel blended with methanol on a Blend of B23 and B58 has been operated on a regular diesel engine. The high-quality pyrolysis fuel acts as a combustion enhancement and has shown that it can make regular diesel engines operate when mixed with methanol, without any upgrade requirements. When using the MASH additive, the fuel blend will be improved in terms of Autoignition temperature, Cetane Enhancement, Lubricity, Calorific value, Maximum Rate of Heat Release etc.

With this groundbreaking approach, shipowners interested in using methanol can completely avoid the CAPEX expenditure of diesel to methanol engine modifications. MASH fuel can be blended in Methanol and directly operated in diesel engines.

For BOILER USE

MASH fuel has been operated in burners, marine boilers and industrial furnaces. The fuel has demonstrated reliable consistent operation. MASH fuel is nearly compliant with various fuel oil specs including ISO8217: 2005, BS 2869:2010, ASTM d396- 18a, IS-MV2, and ASTM d975 10 (Grand 4D).